NIR Reflection of Plastic for Recycling Applications

The importance of NIR reflection spectra has proven to be a reliable method of identifying unique characteristics and properties of various materials, including types of plastics. Different types of plastics may look similar to one another at an initial glance with the naked eye, but evaluating the NIR reflection properties of plastics can reveal just how unique each sample is.

Conducted by: David Ademe, Avantes Inc.

Description of NIR Reflection System:

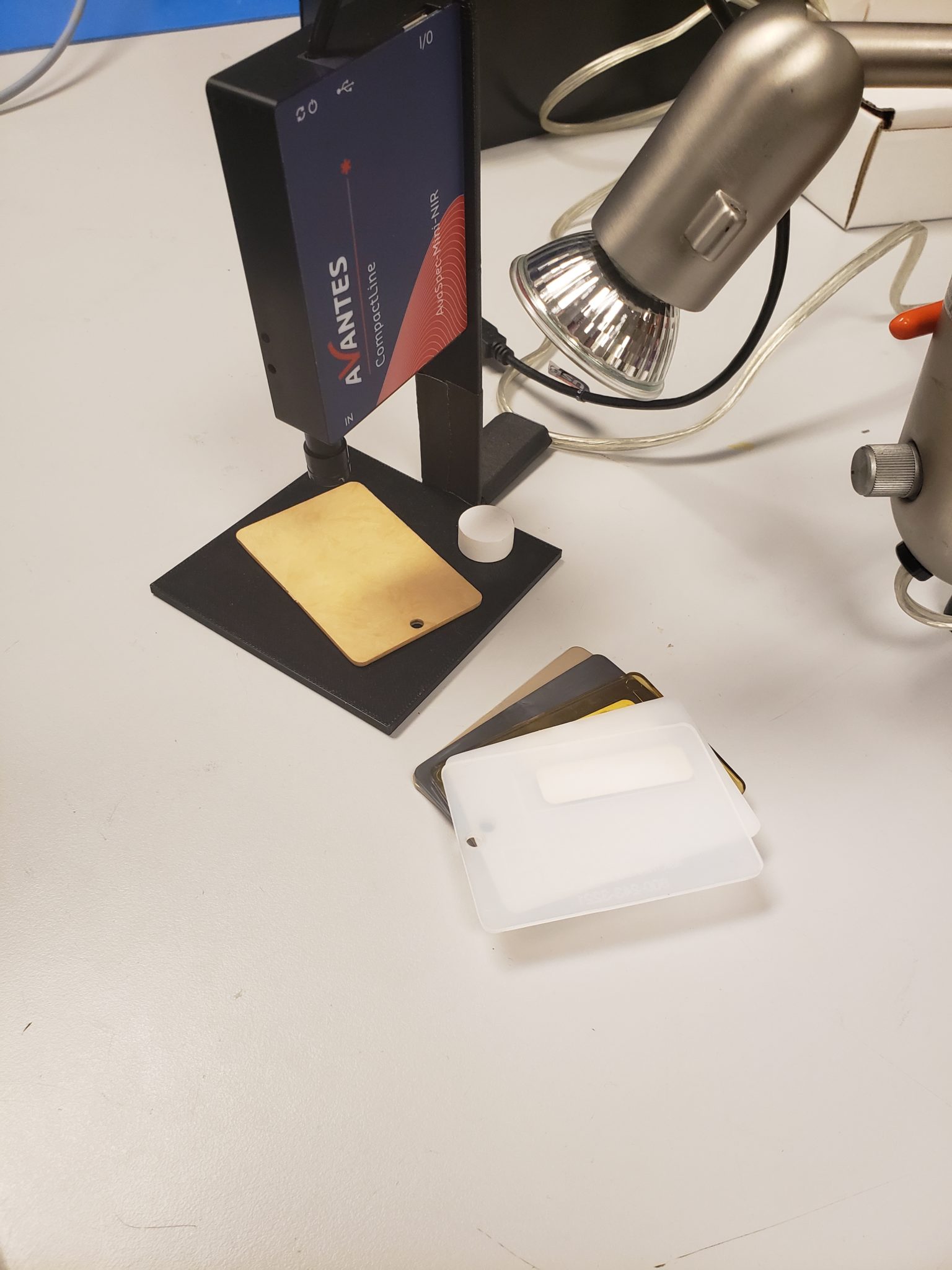

A 100W halogen light source is used to illuminate the plastic samples we have acquired. These samples will be placed on the base of the stand holding the spectrometer, approximately 2 inches away from the slit of the spectrometer. Attached to the SMA connector on the slit of the spectrometer is a direct attach collimating lens to collect as much light as possible from this free space measurement.

For this experiment, the brand new AvaSpec-Mini-NIR will be utilized. The AvaSpec-Mini-NIR is a compact near-infrared spectrometer, based on a combination of our popular AvaSpec-NIR256-1.7 and Mini-series. This NIR spectrometer might not be as sensitive as our bigger NIR spectrometers, but this loss in sensitivity is greatly compensated by its size and robustness. Like our other CompactLine spectrometers, this device is only the size of a deck of cards and USB powered, which makes it easy to integrate into other devices, including but not limited to OEM handheld applications. This versatile miniature NIR spectrometer is well suited for various applications, including food analysis and the recycling industry such as the work from the rubbish removal. Below are some application examples for this instrument:

Figure 1: The setup of the experiment.

- Fertilizer analysis

- Dairy industry

- Recycling

- Wheat and grain analysis

- Moisture content measurements

Description of Methodology:

For this experiment, we used the reflection mode in AvaSoft. This mode is built to capture the NIR reflectance of samples in percent.

Our setup will be used to measure the reflection spectrum of six different types of plastics. The types of plastics we will be looking at are:

- HYDLAR Z – HYDLAR possesses a combination of physical properties that cannot be found in any other commercially available engineered plastic. HYDLAR Z is a family of resistant thermoplastics using aramid fiber reinforced polymer. This technology makes possible for aramid fiber reinforced plastic to be used in combination with a nylon base resin.

- Tecafine LDPE – Polyethylene (PE) polymers are semi crystalline thermoplastics with a high degree of toughness and very good chemical resistance. When compared to other plastics, polyethylene plastic tends to exhibit lower mechanical strength and temperature resistance. This polyethylene is a low-density version (LDPE).

- Tecaform – POM plastic (chemically known as Polyoxymethylene) is a semi crystalline thermoplastic with high mechanical strength and rigidity. Acetal polymer has good sliding characteristics and excellent wear resistance, as well as low moisture absorption. The good dimensional stability and particularly good fatigue strength, as well as excellent machining ability, makes POM polymer a highly versatile engineering material, even for complex components.

- Tecamid 6/6 MDS – The most common extruded nylon is a polyamide 66, which offers a balanced combination of performance and cost that provides users with a unique engineering plastic polymer.

- Tecapeek – PEEK polymer is a high-performance plastic material with an excellent balance of physical properties. It has one of the highest levels of heat resistance and mechanical strength available among plastics. It is also one of the best choices when looking for good chemical resistance, as well as radiation resistance. Click on the list below for detailed PEEK characteristics.

- Ultem – Polyetherimide or PEI material is an amorphous thermoplastic with high mechanical strength and rigidity.

A WS-2 reflection tile will be used as our reference. With the tile, we will use this to optimize the integration time and averaging for the spectrometer in the NIR wavelength range.

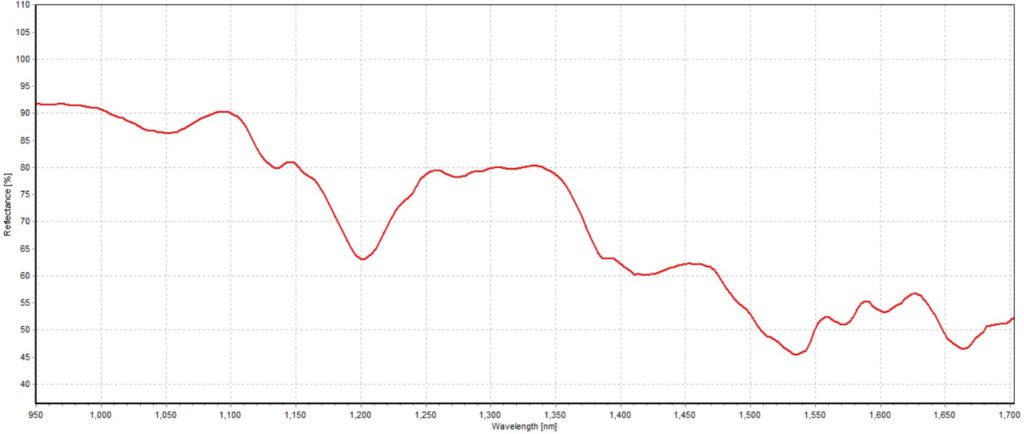

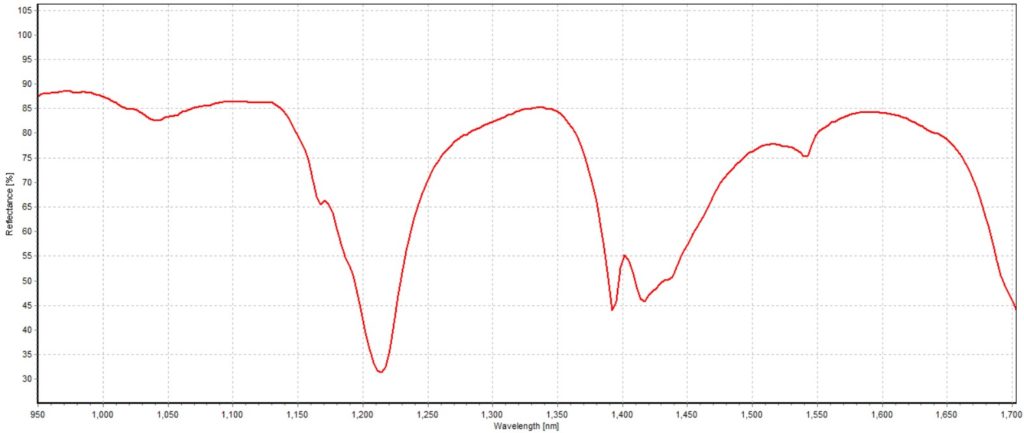

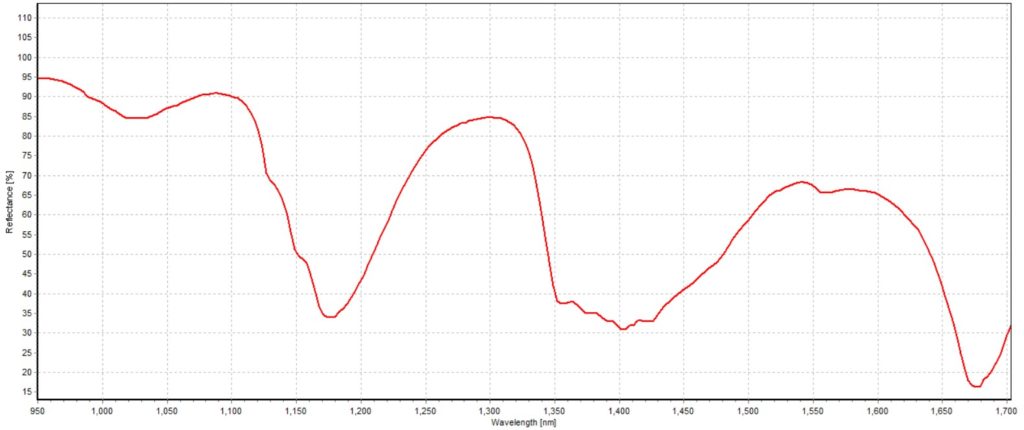

NIR Reflection Test Data and Results:

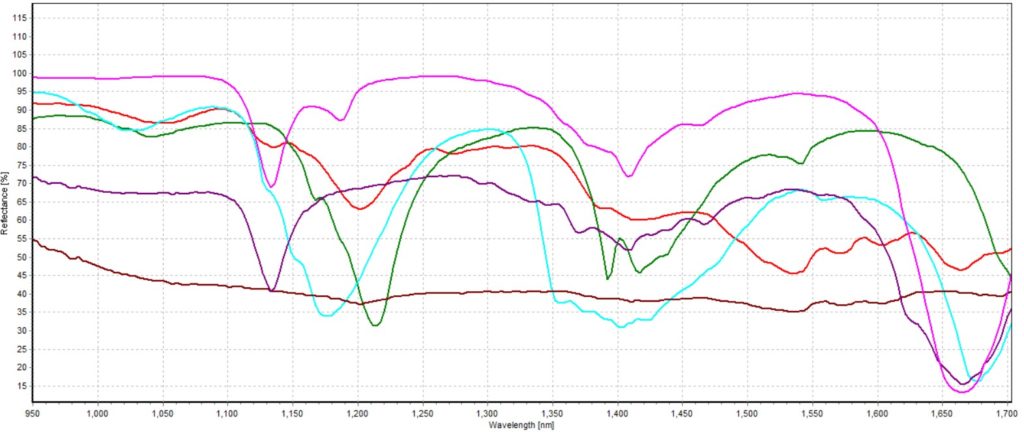

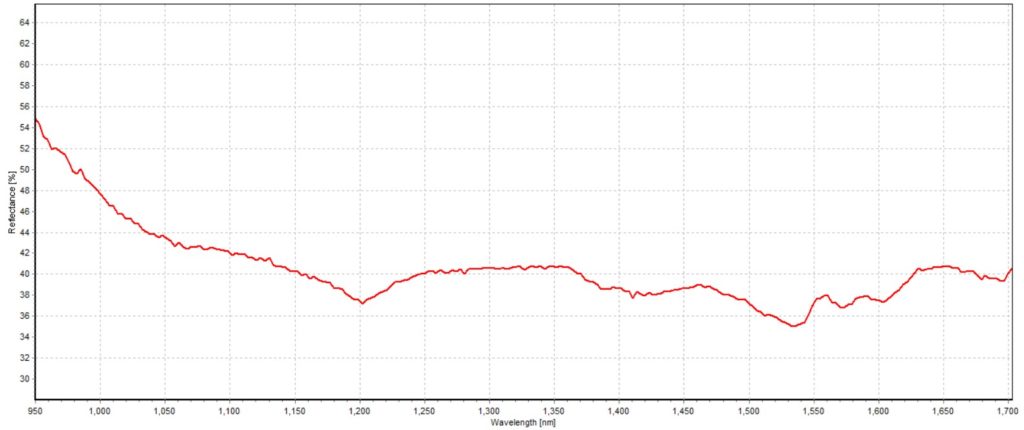

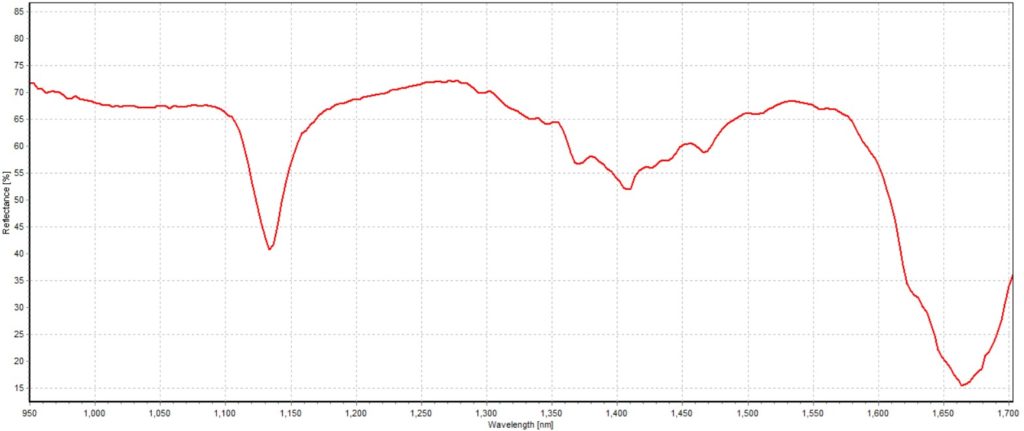

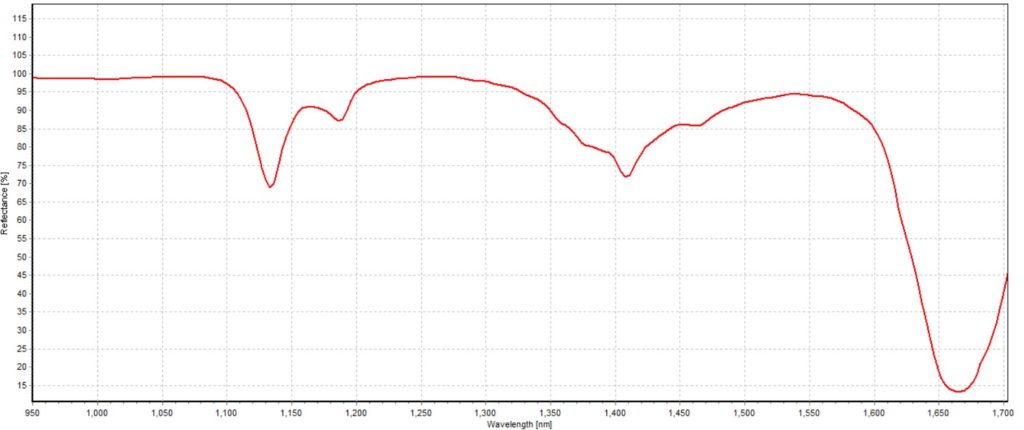

Displayed below is the NIR reflection spectrum collected from the six plastic samples.

Integration time: 35 ms

Averaging: 15

Analysis:

Upon analysis of the various samples, it becomes clear that each plastic sample, while similar in visible appearance and texture, has its own unique spectrum in the NIR region. A chemometric model would be a fascinating next step that would demonstrate the uniqueness of each plastic sample and provides a reliable method of identifying plastics. This model could then be incorporated into a handheld instrument to allow rapid sample identification.

Conclusion:

The new AvaSpec-Mini-NIR from Avantes is an excellent tool that has proven itself useful for not only identifying plastics but also revealing the unique traits of all types of samples in the NIR spectrum. Combining the reliability of the AvaSpec-Mini-NIR with its compact size, this portable spectrometer is an excellent option for handheld applications and fieldwork.

Get the Downloadable Data Files

Explore Applications for NIR Spectroscopy in your Operation

Avantes is a world leader in solutions for NIR Spectroscopy, discover what we can do to streamline your operations with the power of Near-Infrared.

My Cart

My Cart