Reflection Spectra of Thin Film

Posted on: July 16th, 2019

Avantes engineers have been thinking “thin” this month, thin film that is. We are sharing thin film measurement data from a mulit-layer deposition collected through collaboration with Alan Streeter and Boulder Optical Design

Background

Thin film metrology is most often performed offline after a coating run to determine adherence to thickness and uniformity specifications during the deposition process. While this post-process measurement is certainly valuable, implementation of optical monitoring upstream, during the deposition, within a chamber can be far more useful to many coating operations.

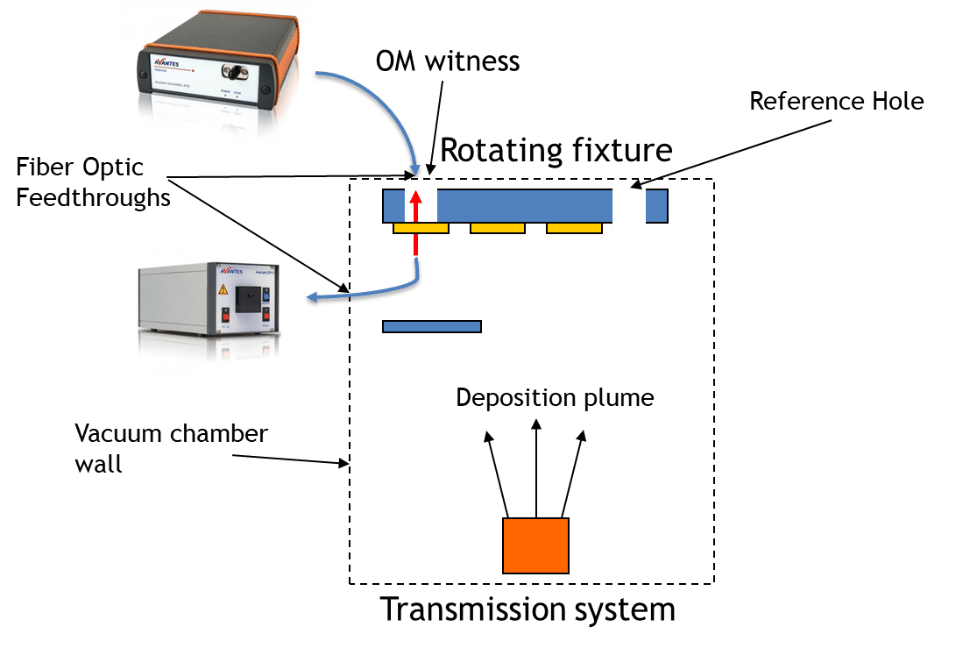

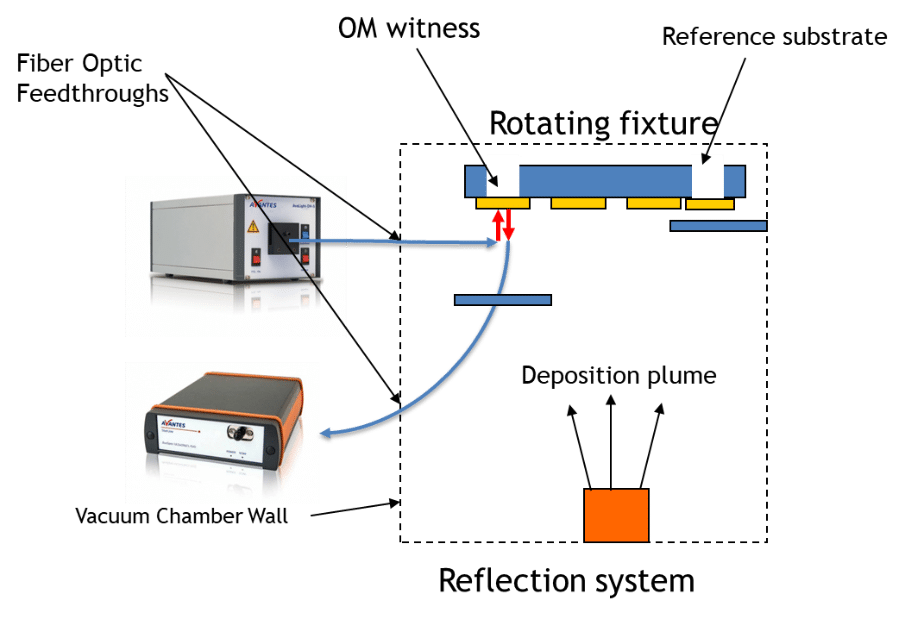

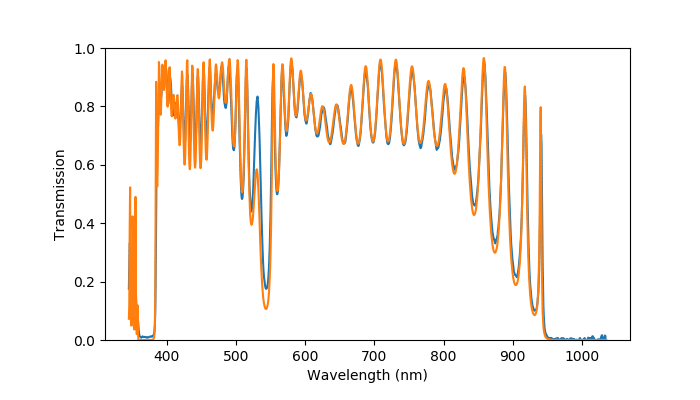

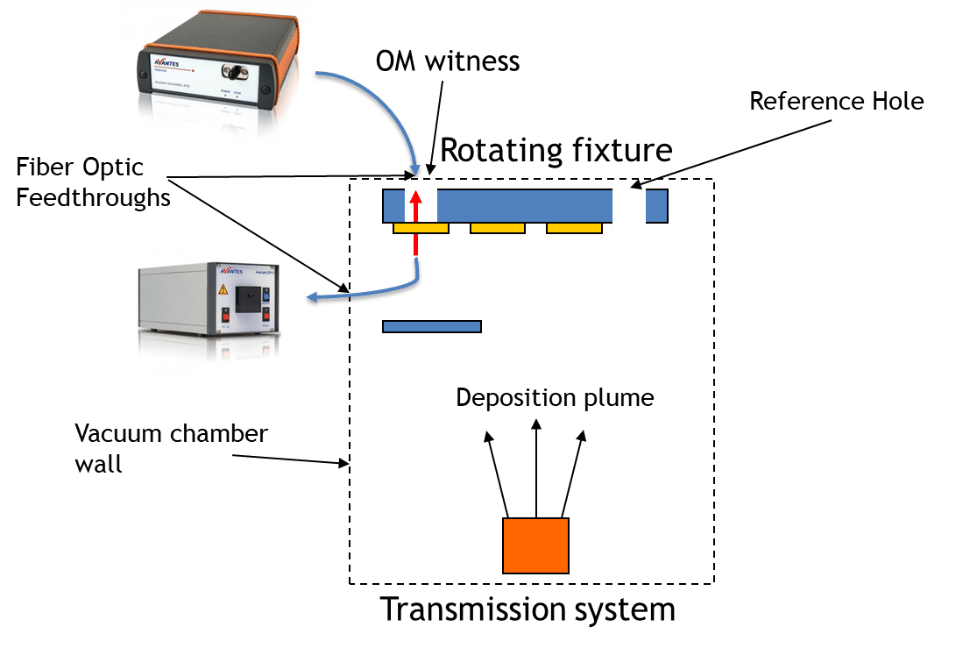

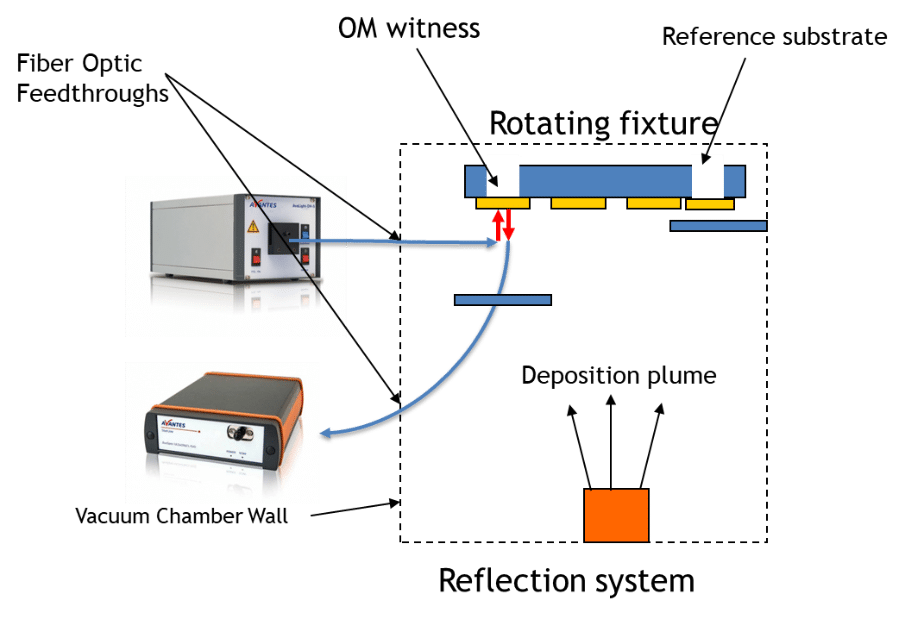

Many Avantes customers integrate optical monitoring into their coating chambers to facilitate inline process control or endpoint detection. This can be accomplished in either transmission or reflection mode as shown in Figures 1 & 2 below.

System Description

|

|

|

| Figure 1 – Transmission coating optical monitoring configuration |

|

|

|

|

|

|

|

| Figure 2 –strong> Transmission coating optical monitoring configuration |

|

|

|

|

|

In Figures 1 & 2 the as the fixture rotates, the optical monitor (OM) witness and the reference hole or substrate both move across the beam at different times. An optical trigger (not shown) facilitates the triggering of the spectrometer at the right moment for both the witness and reference. Transmittance or Reflectance is calculated as follows in real-time for each wavelength.

Transmittance/Reflectance % (T/R%) = (witness spectrum-dark)/(reference spectrum-dark).

Using transmission for this type of monitoring is generally preferable. Reflection needs a very stable rotational system as this measurement is very sensitive to sample vibration and stand-off distance. A broadband optical monitoring system relies on the good characterization of the index of refraction and absorption (n and k) as a function of wavelength.

Avantes recommends the following instruments to facilitate optical process monitoring in a coating chamber.

- Avalight DH-S Broadband deuterium halogen light source.

- AvaSpec-ULS2048CL-EVO spectrometer 200-1100 nm

- FC-UVIR400-2-BX – fiber optic cables 400-micron core (or FCR-7UV200-2-ME reflection probe)

- COL-UV/VIS – Collimating lenses

- FC-VFT-UVIRXX – Optical fiber optic feedthroughs

Thin Film Measurements

Typically optical monitoring requires some level of custom software which can be developed using Avantes AvaSpec DLL software development kit. Below in Figure 3 is an example of an optical monitoring software interface used during a process run.

|

|

|

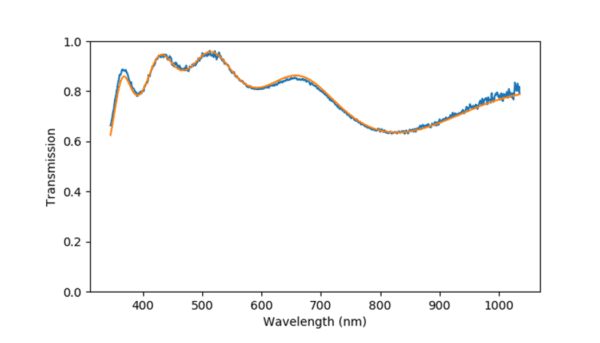

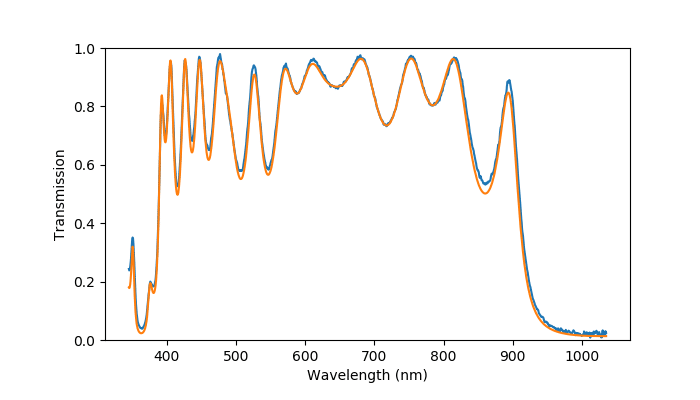

| Figure 4 – Thin film spectrum after 4 layers (image courtesy of Boulder Optical Design) |

|

|

|

|

|

|

|

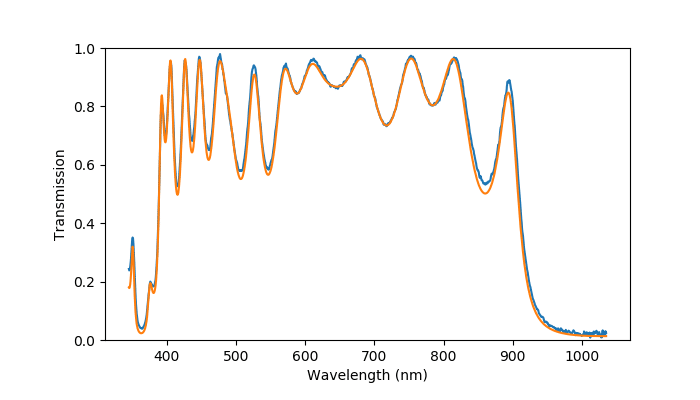

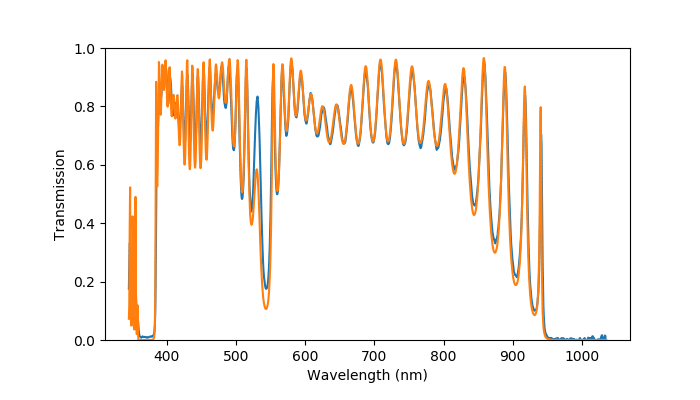

| Figure 5 – Thin film spectrum after 15 layers image courtesy of Boulder Optical Design) |

|

|

|

|

|

|

|

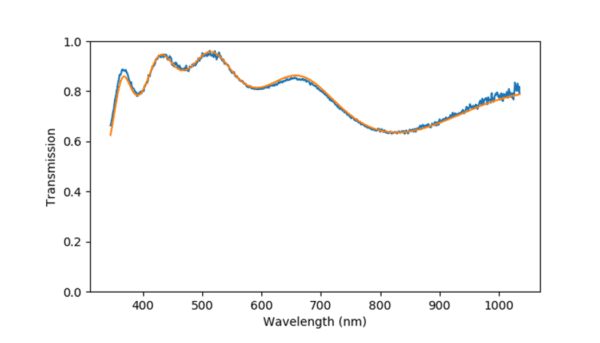

| Figure 6 – Thin film spectrum after 44 layers (image courtesy of Boulder Optical Design) |

|

|

|

|

|

Conclusions

As seen with many Avantes customers, such as Boulder Optical Design, Avantes equipment is perfectly suited for thin film applications and can be configured to meet the needs of your optical process monitoring in a coating chamber. Not only are you capable of collecting thin film data through the Thin Film module in AvaSoft, but you also have the ability of integrating Avantes equipment with your own setup and software through the AvaSpec DLL. Implementing these spectrometers and light sources in your setup can aid in monitoring the adherence to thickness specifications during the deposition process inline, which can ultimately be more useful with many coating procedures.

To learn more about how spectroscopy can solve your measurement needs, or better yet, participate in the test drive demo program and test that solution on site, speak with your local spectroscopy applications expert at Avantes.

My Cart

My Cart